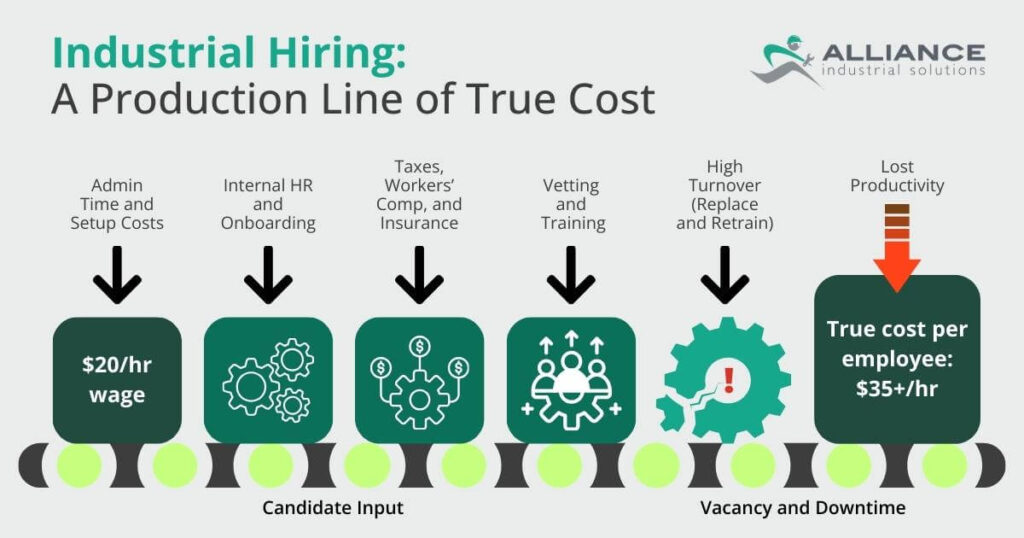

At a Glance:

- The Real Cost: An employee’s hourly wage only accounts for ~65% of their total cost to your business.

- The Burden: Internal hires include hidden costs like FICA, FUTA, SUTA, Workers’ Comp, and benefits.

- Vacancy Impact: A vacant industrial role costs an average of $500–$1,000+ per day in lost productivity.

- The Verdict: Specialist staffing reduces long-term costs by offloading liability and reducing turnover.

If you’re running a manufacturing plant or a distribution center, you’ve likely looked at your labor line item and felt a headache coming on. Wages are up, the “low-hire, low-fire” market has created a weird stagnation, and every time you see a quote for external staffing, your first instinct is to toss it in the bin.

Whether you’re thinking, “I can hire someone for $20 an hour myself,” or you’re out there hunting for the lowest bill rate in town to keep the finance guys happy, we get it. Every penny counts.

But leaning on cheap labor is a lot like hiring the cheapest plumber in the phone book—it feels like a win until your basement is two feet deep in bad decisions and you’re paying a professional double to fix the mess.

The push for the lowest possible price is usually based on a dangerous assumption: that an employee’s hourly wage is their actual cost. It’s not.

In fact, if you’re only looking at the hourly rate or the initial quote, you’re missing about 40% of the equation.

Let’s break down the actual cost of an industrial hire.

The Bill Rate Boogeyman

When you hire internally, you aren’t just paying for the work done. You’re paying for the right to employ that person.

According to the U.S. Bureau of Labor Statistics, total benefit costs for private industry workers averaged 31-39% of total compensation, with legally required benefits making up a significant portion of that ‘hidden’ cost.

In the industrial world—where Workers’ Comp rates for a guy on a shearing machine are much higher than a guy sitting at a desk—that burdened cost is almost always on the higher end of that average scale.

If you’re paying a welder $25.00/hour, your actual cost before they even pick up a torch is closer to $35.00/hour.

| Cost Component | Internal Hire (You Pay) | Staffing Partner (They Pay) |

|---|---|---|

| Base Hourly Wage | $20.00 | Included |

| Payroll Taxes (FICA, FUTA, SUTA) | ~10 – 14% (varies by state) | Included |

| Workers’ Comp Insurance | 2% – 15% (industry dependent) | Included |

| Health & Retirement Benefits | $15,000 – $25,000/year [1] | Included |

| Recruitment & Sourcing | $4,700 average per hire [2] | Included |

| Liability & Risk | 100% on you | 100% on partner |

The Silent Killer: Cost of Vacancy

Here is the question that really matters: What is the daily cost of that machine sitting idle?

If your forklift is parked or your assembly line is running at 70% capacity because you’re waiting for the right candidate to apply on Indeed, you are hemorrhaging cash.

In manufacturing, the cost of vacancy is a silent killer. When a position stays open for the national average of 30–45 days, it’s not saving you a wage; it’s costing you production.

This leads to the Hidden Operational Tax:

- Overtime Burn: Paying 1.5x to your tired “A-players” just to keep the lights on.

- Maintenance Issues: Tired workers are statistically harder on equipment.

- The Ripple Effect: One vacancy often leads to a second resignation because the remaining crew is burnt out from carrying the extra load.

Why Cheap Labor is Your Most Expensive Purchase

We’ve all been there: You find a guy who’s willing to work for $2 less than the market rate. Two weeks later, he ghosts the shift, or worse, backs a forklift into a $50,000 rack system.

Cheap labor isn’t effective; it’s just risky. When you prioritize the lowest bill rate, you are effectively asking for lower-tier vetting, higher turnover (which costs $4,700+ per quit), and increased safety risks.

As the old saying goes: If you think a professional is expensive, wait until you hire an amateur.

Why AIS? Because Industrial Staffing Is All We Do.

Our specialty focus on manufacturing, logistics, and warehouse operations means we aren’t learning on your dime. We have a pipeline of industrial talent that we’ve been nurturing while you were busy trying to fix that conveyor belt for the third time this week.

We handle the taxes, the insurance, the vetting, and—most importantly—the risk.

As our leadership team likes to say: You’re paying for a collaborative partnership, not a transaction.

You’re paying for the fact that we actually pick up the phone, we understand your service levels, and we communicate like your business depends on it, because it does.

Our goal is to give you back the one thing you can’t buy more of: time.

When Should You NOT Use a Specialized Partner?

In the spirit of being straight with you, a specialized industrial staffing firm isn’t the right choice for every situation. You probably shouldn’t reach out if:

- You just want the lowest bill rate in town. We don’t cut corners on vetting, background checks, or safety. Our pricing reflects the fact that our people actually show up and stay.

- You’re looking for a temporary band-aid. If you don’t care about retention or long-term operational stability, a national chain or “big box” agency is a better (and cheaper) fit.

We’re here for the operations managers who are tired of paying the hidden costs of bad staffing. If you’re okay with paying a fair rate to get the job done right the first time, then we’re going to get along just fine.

The Bottom Line

We’re not here to be the cheapest line item on your budget; we aim to be the most reliable one. Hiring based on cost alone is a gamble with your production schedule and your sanity.

If you’re staring at a budget and wondering if you can afford the fee, ask yourself:

1. What does the budget look like if a “cheap” hire breaks a $20k piece of equipment on day one?

2. What is it costing you right now to keep that position empty?

3. Would it make sense to see the caliber of talent we can find for the fee we’re asking, or is it time for another prayer and a Craigslist ad?

Want to see the math on your specific facility? Contact Alliance Industrial Solutions today and let’s stop the bleeding.

SUCCESS STORY:

Outsourcing That Resulted in 48 hours Time-To-fill And Lower Turnover